FOR IMMEDIATE RELEASE: TSP, INC. Achieves ISO 9001 Certification. Batavia, Ohio – June 22, 2020 TSP, Inc., an industry leader in protective plastic for durable viewing applications, is pleased to announce today that it has earned ISO 9001 Certification. The comprehensive system audit covers every aspect of operations.

Quick turnarounds on printed plastic lenses for durable display devices can be difficult to achieve. The reason? Long leadtimes for artwork, plate and screen development. TSP solves this problem utilizing our new state-of-the-art, in-house, inkjet UV-LED printing process, which can turn around finished printed parts in hours vs. days by traditional printing methods.

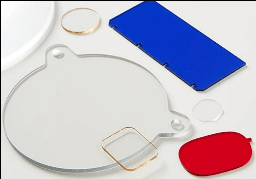

TSP can provide them for: optoelectronic display fronts, instrument cluster panels, contrast enhancement filters, ruggedized flat panel displays, bar-code scanner windows, moving message board signs, and much more. Whatever your protective viewing application, TSP has a quality, cost-effective, high-performance DURAVUE® solution for you.

Glass? Plastic? Which Plastic? When building a product that involves displayed images and/or transmitted critical optical information, especially mobile computing units, you are faced with an important design decision: Which material is the best? Lets first look at what features are important for an optimum functioning window.

Q: Why would I use a plastic window, filter or lens instead of an alternative like glass? A: Plastics with a DURAVUE® coating offers improved Durability and Design Flexibility. Durability: Glass is not suitable for most high traffic or portable product applications due to its susceptibility to breakage upon impact.

Quick turnarounds on working pre-production units for durable display and data acquisition devices can be difficult. Do you find yourself in these situations? You know basically what you need, but not how to get there to create a finished working prototype (molding, coating, fabrication, printing, fastening and assembly).

You have a plastic window and are unsure of how to bond it to your display or data acquisition device – what is the best method? Liquid Glue? Sonic Welding? Adhesive Tape? Liquid glue is difficult to apply and messy. Sonic welding takes specialty equipment, is limited to certain materials and requires 3D geometries.

One of the main benefits of any supplier is our knowledge and expertise in the product field or service we provide. This expertise can be accessed in many ways, but the most productive way is in-person, face-to-face meetings. However, in todays world in-person visits are severely limited, which prevents you from taking full advantage of our insight.

See it for yourself! Kit contains hardcoated plaques with each of our DURAVUE® coatings.

See it for yourself! Kit contains hardcoated plaques with each of our DURAVUE® coatings.

Need a pre-production sample? Let us provide you with a fully functional prototype window.

Need a pre-production sample? Let us provide you with a fully functional prototype window.

Tell us about your project and we’ll provide you with a budgetary quotation.

Tell us about your project and we’ll provide you with a budgetary quotation.