Coated Acrylic Frequent Questions

We apply coatings to resist scratch and abrasion and reduce glare and reflection on acrylic plastic. There are datasheets on each coating located under the “Datasheets” tab at the top of every page on our website. Note that we don’t sell acrylic coatings: we COAT acrylic.

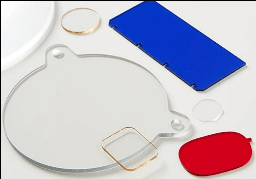

We work with rigid acrylic (>0.030” thickness), in both sheet and molded (3D) form.

TSP has the capabilities to coat via flow, dip or spray and cure via thermal or UV energy. All coatings are applied in a Class 10,000 Cleanroom. The method used for your particular application is determined by which produces the highest quality most economically for your particular use.

Yes, depending on the part geometry. Location and size of lips, holes, edges, etc. will determine coating feasibility. Supply us with a sample acrylic part or part drawing and we can provide you with a quick assessment.

Yes and yes. We can supply you with a coated acrylic sheet or sheet blank, or supply you with a finished, fabricated flat part. We have full fabrication capabilities – lasercutting, CNC, precision saw cutting, etc. – to finish out your part so it is ready-to-install.

We can handle AR coat jobs up to 12” x 12” in size (please consult the DURAVUE® 7000 datasheet). Larger AR parts are assessed on a case-by-case basis.

Unit cost is a function of many factors, including: size, thickness, material, quantity, type of coating and in-use cosmetic acceptance criteria. By supplying us with these inputs we can quickly provide you with a quotation.

TSP’s siloxane-based DURAVUE® hardcoats are high-performance coatings, meeting or exceeding the most stringent requirements of Automotive, DoD (Military), Aerospace, and Electronic OEMs around the world.

See it for yourself! Kit contains hardcoated plaques with each of our DURAVUE® coatings.

See it for yourself! Kit contains hardcoated plaques with each of our DURAVUE® coatings.

Need a pre-production sample? Let us provide you with a fully functional prototype window.

Need a pre-production sample? Let us provide you with a fully functional prototype window.

Tell us about your project and we’ll provide you with a budgetary quotation.

Tell us about your project and we’ll provide you with a budgetary quotation.