Plastic Coating Services

Plastic Coating Services for Polycarbonate and Acrylic

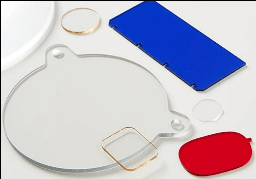

TSP offers siloxane hard coating services for customer supplied polycarbonate and acrylic sheet, and injection molded or formed plastic 3D parts to resist scratch and abrasion and reduce glare. Note: we do not sell hard coatings for plastics; we hard coat plastics.

TSP has the capabilities to coat via flow, dip or spray and cure via thermal or UV energy. All coatings are applied in a Class 10,000 Cleanroom. The method used is determined by which produces the highest quality, most economical result for your particular application.

- DURAVUE® 1000 optical applications

- DURAVUE® 1500 outdoor applications

- DURAVUE® 2000 high resolution anti-glare hardcoat

- What Makes DURAVUE® Coatings Superior?

Request a Custom Sample

Need a pre-production sample? Let us provide you with a fully functional prototype window.

Need a pre-production sample? Let us provide you with a fully functional prototype window.

Request Custom Sample

Founded in 1983, our firm began as a contract “toll” coating house specializing in siloxane hard coating of polycarbonate sheets and parts. We have extensive experience in the field of hard coating of polycarbonate and acrylic. In 1988 a full-size plastic sheet coating line was added, and in 1994 we moved into our own state-of-the art production facility located in Batavia, Ohio. There we installed an expanded and modernized coating cleanroom.

TSP’s proprietary coatings were officially recognized and Registered as DURAVUE® in 1999. In 2020 we achieved ISO 9001:2015 Quality System Certification, recognition that our coating facility operates at ISO standards for quality management systems. Conformance to these standards ensures that TSP maintains the highest level of product quality and process control in our coating operations.

Throughout our 30+ years in existence, we have become a leading supplier of durable plastics for protective viewing applications for many of the world’s largest and most demanding enterprise companies in the aerospace, electronics, safety and security, transportation, military/defense and medical fields. We encourage you to talk to us about your part and how we can assist you in getting it hard coated.

See it for yourself! Kit contains hardcoated plaques with each of our DURAVUE® coatings.

See it for yourself! Kit contains hardcoated plaques with each of our DURAVUE® coatings.

Tell us about your project and we’ll provide you with a budgetary quotation.

Tell us about your project and we’ll provide you with a budgetary quotation.