DURAVUE® Scratch Resistant Coatings for Polycarbonate and Acrylic Plastics

Q: What makes DURAVUE® scratch resistant coatings for polycarbonate and acrylic superior?

A: Use thermally cured, polysiloxane hardcoat technology, flowcoated

- Harder

- More Weatherable

- Chemical Resistant

- Superior Appearance

- Easier to Clean

- DURAVUE® 1000optical applications

- DURAVUE® 1500outdoor applications

- DURAVUE® 2000high resolution anti-glare hardcoat

- Plastic Coating Services

Request a Custom Sample

Need a pre-production sample? Let us provide you with a fully functional prototype window.

Need a pre-production sample? Let us provide you with a fully functional prototype window.

Request Custom Sample

Harder

Polysiloxanes are more robust compounds than most alternative scratch resistant coatings, evidence their extensive use in the most demanding industrial applications like automotive headlight lenses, architectural glazing and military ballistic windows. DURAVUE® thermal cure polysiloxane coatings provide a more complete cure so are harder, using thermal energy over a longer period to carry out a more complete reaction than quick-cure UV.

Superior Appearance

You will achieve a higher gloss & DOI (Distinctness of Image) from flow (or dip) coating vs. UV spray coating. UV spray coating can give an “orange peel” appearance due to its rapid cure, where the coating is “deposited” on the surface and then held in place so it can be cured quickly in its captured location. This lends itself to the dimpled or “orange peel” affect common to UV curing. Flowcoating allows the coating to flow freely across the plastic surface, completely wetting the surface and taking away any debris that was on the surface.

With thermal cure, the coating is hardened over a longer time period, allowing it to complex to its completely hardened state under less stressed conditions. As a result, DURAVUE® coatings provides a water clear, optically clear, hard surface because of a) the purity of its ingredients (fully complexed siloxane polymer), and b) the process in which it is applied.

More Weatherable

Most plastics like polycarbonate degrade under UV and sunlight exposure, resulting in a dull, yellowish appearance. DURAVUE® hardcoats retard degradation by sealing up the surface to water and other environmental agents. With UV inhibitors added, the DURAVUE® coating absorbs or reflects the damaging UV radiation, preventing it from getting to the plastic. UV-cure hardcoats typically involve organic components that degrade over time and exposure to sunlight and UV. With UV-cure coatings it is hard to perform both UV inhibiting and UV activation/curing at the same time. Siloxane-based hardcoats like DURAVUE® are derived from inert, inorganic compounds, so do not have the degradable components that most organic UV hardcoats possess.

Easier to clean

DURAVUE® coatings have a lower surface energy than other hardcoats, resulting in a slicker, smoother surface. This makes it harder for debris to stick to it, and is therefore easier to remove with a soft cloth or light duty surface cleaning fluids. For this same reason, DURAVUE® coatings are also more resistant to graffiti.

Chemical resistant

Because of its inorganic polysiloxane structure, DURAVUE® coatings are highly resistant to all but the strongest acid and base chemicals. With most plastics highly susceptible to chemical attack, use of a DURAVUE® coating is essential to allowing the use of plastics, like polycarbonate and acrylic, in environments where chemicals pose a risk to long term usage.

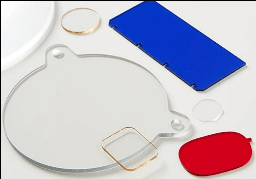

See it for yourself! Kit contains hardcoated plaques with each of our DURAVUE® coatings.

See it for yourself! Kit contains hardcoated plaques with each of our DURAVUE® coatings.

Tell us about your project and we’ll provide you with a budgetary quotation.

Tell us about your project and we’ll provide you with a budgetary quotation.